Valves for Your New Factory Water System

Release time:2025.08.21

How to Choose the Right Valves for Your New Factory Water System

When building a new factory, selecting the right valves for your water system is crucial. Efficient flow control, reliability, and durability are top priorities for procurement managers looking to avoid future maintenance headaches.

Consider Your System Requirements

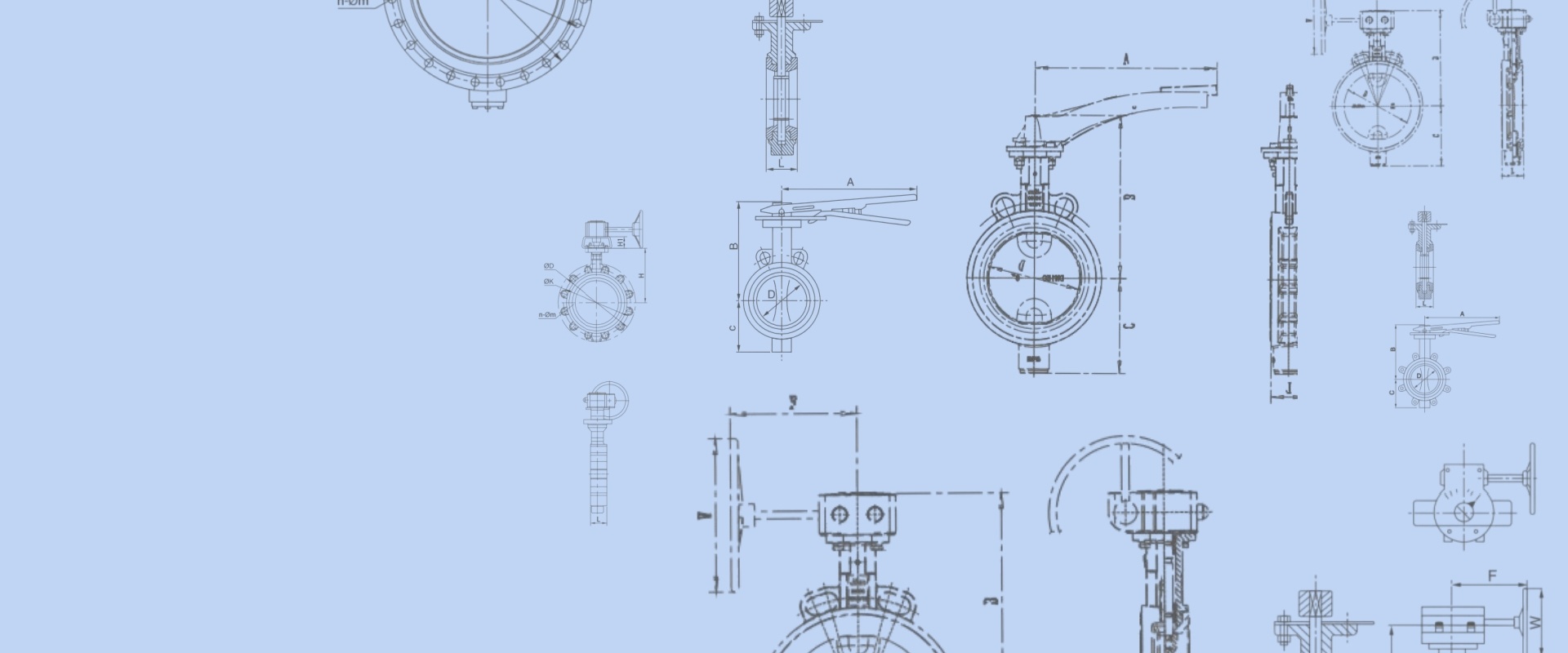

Start by evaluating the flow rate, pressure, and temperature of your water system. Different types of valves, such as gate valves, butterfly valves, and ball valves, are suitable for different applications. Understanding these requirements helps in selecting valves that optimize system efficiency.

Material Matters

Choosing the correct material ensures longevity and resistance to corrosion. Stainless steel, brass, and cast iron are commonly used materials for industrial water systems. Procurement teams should consider both initial cost and long-term maintenance implications when selecting materials.

Compliance and Standards

Make sure all valves comply with local and international standards. Certifications such as WRAS for drinking water, CE marking in Europe, or ANSI ratings in the US can prevent regulatory issues and ensure system safety.

Partner with Reliable Manufacturers

For new factory projects, sourcing from trusted valve manufacturers who offer OEM/ODM services can save time and provide customization options. Experienced suppliers understand procurement needs and can recommend the right products for your water system.

Looking for reliable valves for your factory project?

Contact us today: sales@juhanvalve.com | Phone: +86 150 6232 6088