Valve Seals & Material Classification

Release time:2025.09.02

Valve Seals • Material Classification

Valve Seal Material Classification & Properties

Choosing the right seal material is critical to valve performance, reliability, and service life. This guide outlines the main categories of valve seal materials, their typical applications, temperature and chemical compatibility, and common standards.

What You'll Learn

Common seal materials: elastomers, PTFE, metal, graphite, and composite.

Material selection based on temperature, pressure, and fluid compatibility.

Regional and international standards for sealing materials (ASTM, EN, JIS, ISO).

Applicable Valves

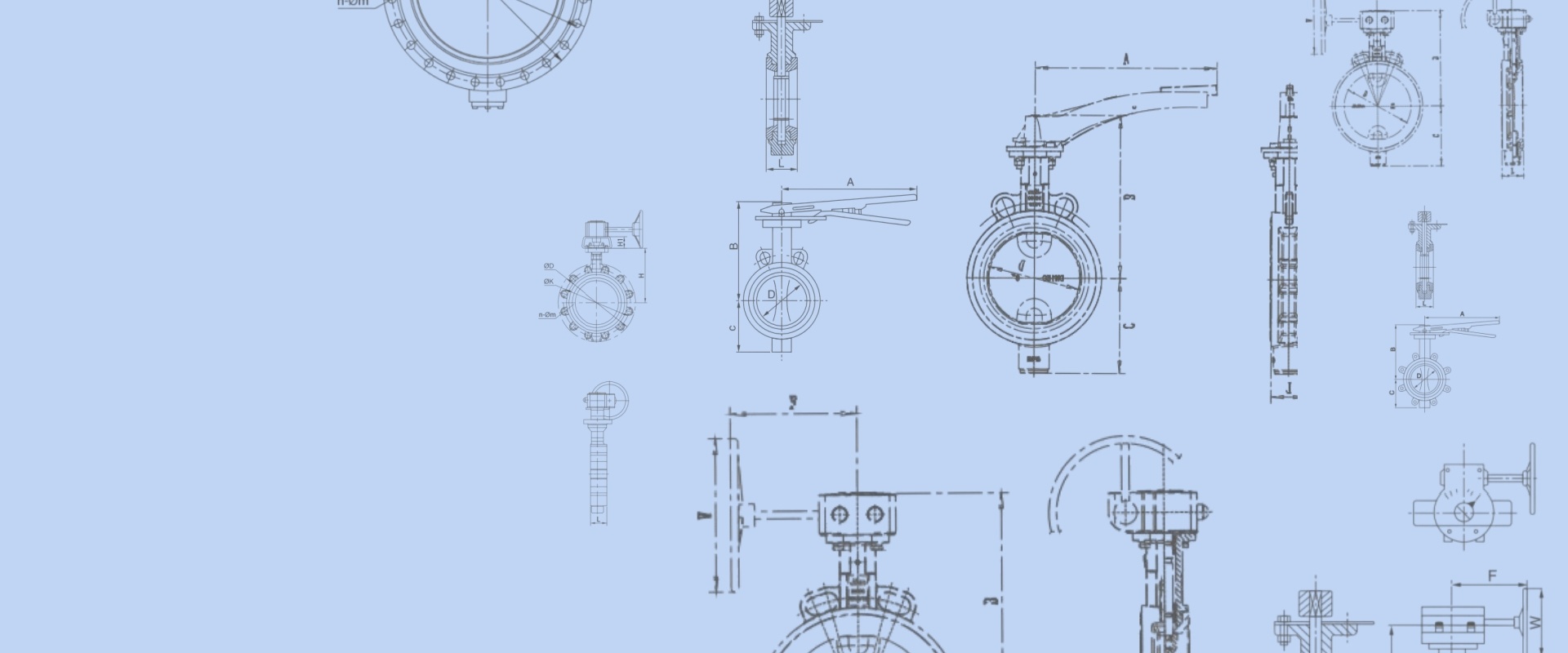

Gate, Globe, Ball, Butterfly, Check

Gate, Globe, Ball, Butterfly, Check

Inspection Focus

Hardness, Chemical Resistance, Temperature, Wear

Hardness, Chemical Resistance, Temperature, Wear

NBR (Nitrile) EPDM FKM / Viton

Temperature

-40°C to 150°C (depends on type)

Fluids

Water, oils, fuels, mild acids/bases

Standards

ASTM D2000, ISO 3302

2) PTFE / Teflon

Virgin PTFE Filled PTFE (Glass, Carbon, MoS2)

Temperature

-200°C to 260°C

Fluids

Most chemicals, aggressive media, steam

Standards

ASTM D4894, EN 607

3) Metal Seals

Stainless Steel Copper Inconel / Monel

Temperature

Up to 600°C+

Applications

High pressure, high temperature, or vacuum valves

Standards

ASME B16.20, EN 12516

4) Graphite

Flexible Graphite Spiral Wound Gaskets

Temperature

-200°C to 450°C

Fluids

Steam, acids, caustics, high temp oils

Standards

EN 1514, ASTM F104

5) Composite / Hybrid Seals

PTFE + Elastomer Graphite + Metal

Applications

Enhanced chemical resistance + spring loading for tight sealing

Standards

ISO 3601, EN 13555

Bottom Line: Selecting the correct seal material is key to valve performance, longevity, and leak-free operation. Consider temperature, pressure, fluid type, and standards when making your selection.