Valve Material & Quality Verification

Release time:2025.09.02

Valve Material • Quality Verification

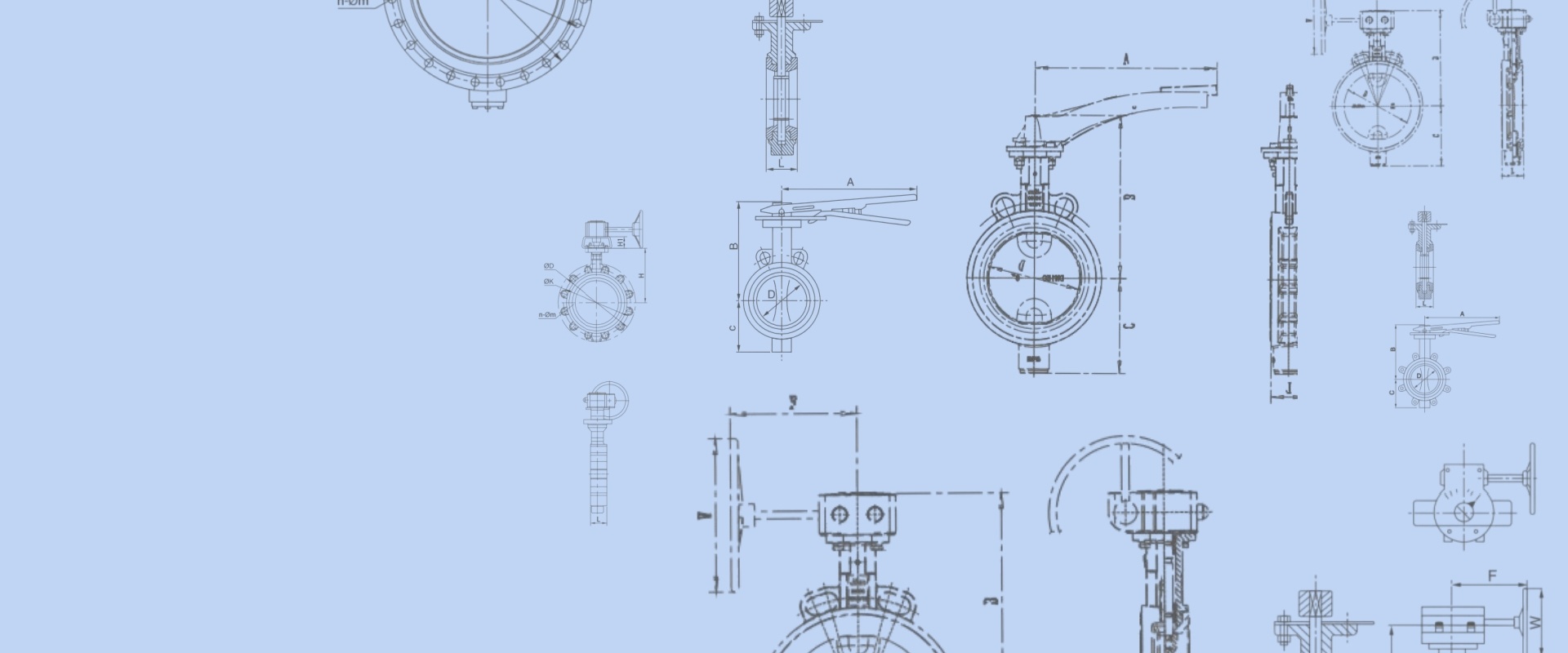

How to Verify the Quality of Valve Raw Materials

Ensuring raw materials meet the specifications is the first step to producing high-quality valves. This guide provides comprehensive methods—from chemical composition and mechanical properties to metallographic and visual inspections—to help engineers and quality inspectors quickly assess material compliance.

Key Verification Methods

Chemical Analysis: Use spectrometers or chemical reagents to verify elemental composition, ensuring compliance with ASTM/EN/JIS standards.

Mechanical Testing: Tensile tests, hardness, and impact testing to confirm strength, ductility, and toughness.

Metallographic Examination: Inspect microstructure to ensure fine grains, no inclusions, and absence of cracks.

Visual Inspection: Check surface for cracks, porosity, inclusions, and ensure dimensions and tolerances match design.

Special Tests: Corrosion resistance, magnetism, heat treatment status, and additional tests depending on material type.

Applicable Materials

Carbon Steel, Stainless Steel, Alloy Steel, Copper Alloys

Carbon Steel, Stainless Steel, Alloy Steel, Copper Alloys

Tools & Equipment

Spectrometer, Universal Testing Machine, Hardness Tester, Microscope

Spectrometer, Universal Testing Machine, Hardness Tester, Microscope

ASTM/EN/JIS Standards Spectrometer Test Chemical Reagent Comparison

Objective

Verify C, Si, Mn, Cr, Ni and other elements meet standard requirements.

Note

Batch differences may affect strength or corrosion resistance.

Mechanical Testing

Tensile Test Hardness Test Impact Test

Objective

Ensure strength, toughness, and ductility meet design requirements.

Tools

Universal Testing Machine, Hardness Tester, Charpy Impact Tester

Metallographic Examination

Microstructure Grain Size Inclusion Check

Objective

Check for internal defects, ensure uniform structure without cracks or inclusions.

Tools

Optical Microscope, Scanning Electron Microscope (SEM)

Visual Inspection

Dimension Measurement Surface Defects Tolerance Verification

Objective

Ensure smooth surface, no cracks, porosity, or inclusions, and dimensions meet design tolerances.

Tools

Vernier Caliper, Micrometer, Visual + Magnifying Glass

Summary: Valve raw material inspection includes chemical composition, mechanical properties, metallography, and visual checks. Each step is crucial to ensure final valve quality and long-term reliability.