Valve Procurement

Release time:2025.08.18

Valve Procurement — End-to-End Industrial Guide

Successful valve procurement requires more than price comparison. It blends engineering fitness-for-purpose, international standards compliance, supplier capability, and lifecycle economics. This guide covers evaluation criteria, a cross-standard comparison table, and a practical, auditable procurement flow.

1) Scope & Requirements Definition

Begin by translating process conditions into technical requirements. At minimum capture: fluid, solids content, corrosion risk, design pressure/temperature, valve function (on/off vs. throttling), allowable pressure drop, end connections, and automation needs.

Key inputs

- Service: Potable water / wastewater / chemicals / steam / hydrocarbons.

- Pressure class: PN10–PN25 (water) or ASME Class 150–600+ (process).

- Temperature: Min/Max, transients, potential water hammer.

- Materials: DI/CI, carbon steel, stainless (304/316), bronze, special alloys.

- Standards target: EN 1074 (water), AWWA C509/C515 (resilient seat), API 600/602 (steel gate), ISO 5208 (pressure test).

2) Standards & Compliance — Comparison Table

Use the matrix below to align project geography and service with the most suitable standards framework.

| Standard | Typical Region | Valve Category | Key Focus | Common Use Case |

|---|---|---|---|---|

| EN 1074-1/2 | EU / Global | Waterworks valves (incl. gate) | Fitness for purpose; hygiene; endurance | Municipal potable water isolation valves |

| AWWA C509 / C515 | NA / Global projects | Resilient seated gate valves | DI body; EPDM/NBR seat; hydrostatic tests | Distribution mains, ductile-iron RS/ NRS gate |

| API 600 / 602 | Global (energy) | Steel gate valves | Wall thickness; materials; trim; testing | Refineries, high-temp/high-pressure service |

| ISO 5208 | International | All valve pressure testing | Leakage rates A–G; hydrostatic/pneumatic | Factory acceptance test reference |

| EN 558 / ISO 5752 | International | Face-to-face dimensions | Interchangeability; footprint control | Retrofit and like-for-like replacement |

| EN 1092-1 / ASME B16.5 | EU / NA | Flanges & pressure classes | End connection compatibility | Ensuring mating flange match |

| ISO 5211 | International | Actuator mounting | Pad patterns; torque transmission | Electric/pneumatic actuation readiness |

| EN 12266-1 / API 598 | EU / Global | Valve testing (method) | Shell & seat tests; test media; acceptance | Inspection & FAT acceptance criteria |

Specification checklist

- Declare standard & revision (e.g., AWWA C515-latest).

- Define pressure/temperature rating and end connections.

- State coatings (FBE ≥250 µm) and potable approvals (WRAS/NSF) if required.

- Include testing protocol (EN 12266-1, leakage rate) and documentation pack (MTC, ITP, FAT).

3) Supplier Qualification

Prioritize manufacturers with traceable quality systems and repeatable processes.

- Quality: ISO 9001; procedure-based hydro tests; calibrated gauges.

- Process: Casting control, shot-blasting, FBE coating cure records.

- Compliance: CE/UKCA; potable approvals (NSF/WRAS) where applicable.

- Support: OEM/ODM capability; spare parts; actuator sizing assistance.

- References: Recent similar projects; third-party audits (BV/SGS/TÜV).

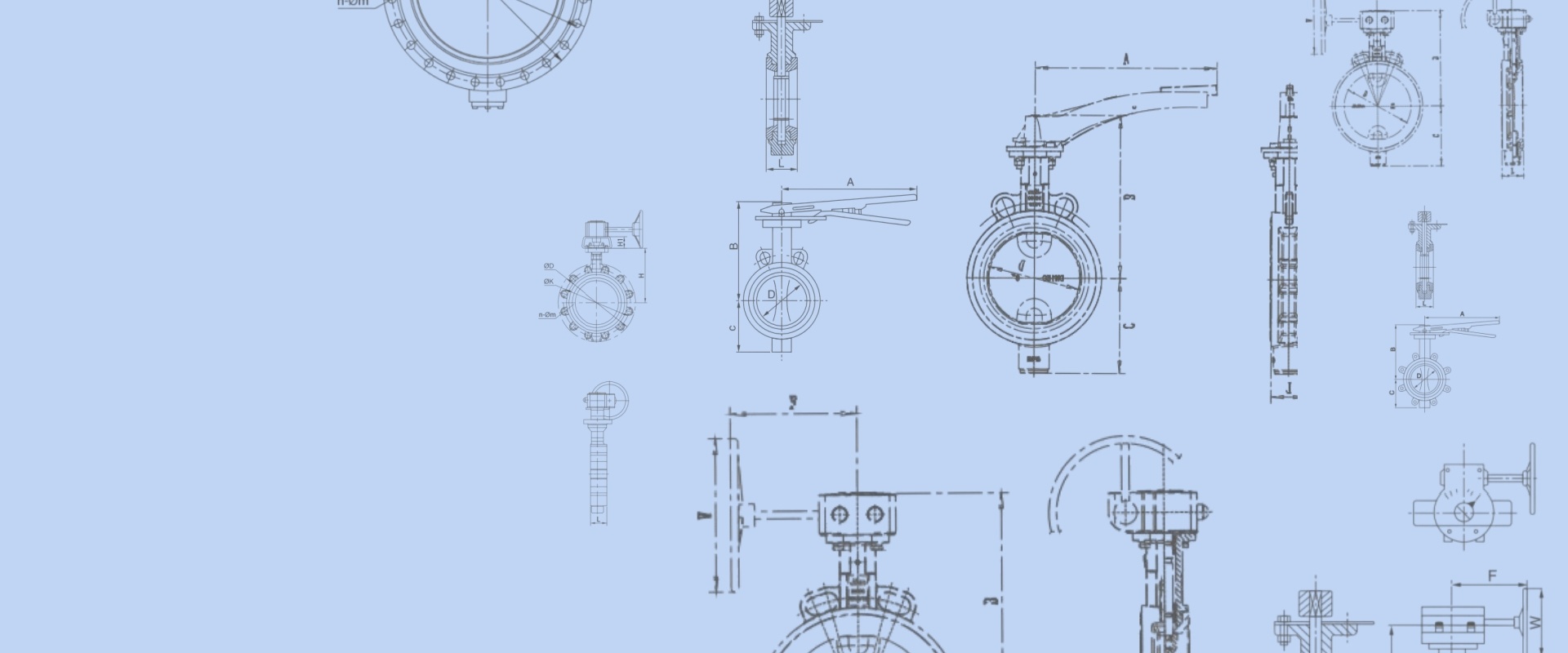

4) Procurement Flow — Visual Timeline

5) Lifecycle & Total Cost of Ownership (TCO)

Balance CAPEX with OPEX. A resilient seated gate valve to AWWA C515 or EN 1074 with robust FBE can reduce leak losses and extend service intervals.

- Spare parts list & availability window (≥10 years recommended).

- Seat/wedge replacement ease; bonnet gasket standardization.

- Actuation readiness (ISO 5211 pads; torque margins ≥25%).

- Corrosion management (coating thickness, holiday testing, hardware SS fasteners).

6) Quick Selection Hints

- Potable water mains: DI gate, resilient seat; EN 1074 or AWWA C515; FBE ≥250 µm.

- High-temp process: API 600 steel gate; stellite trim; API 598 testing.

- Underground service: NRS gate with encapsulated wedge; anti-corrosion stem hardware.

- Remote control: ISO 5211 pad; bevel gearbox or electric actuator; enclosure to IP68 if flooded.

Conclusion

A disciplined valve procurement approach—anchored in standards alignment, supplier capability, and lifecycle thinking—reduces risk and boosts reliability. Use the comparison table to lock standards early, follow the timeline to maintain auditability, and track KPIs to drive continuous improvement across projects.