Comprehensive Guide to Water System Gate Valves

Release time:2025.08.18

Comprehensive Guide to Water System Gate Valves

Water system gate valves are essential for controlling water flow in pipelines. They provide precise shut-off and reliable operation in industrial and municipal applications. This guide covers various types of gate valves, their operating principles, and suitable working conditions.

1. Non-Rising Stem Resilient Seated Gate Valve (Brass Nut Type)

The non-rising stem resilient seated gate valve with brass nut is compact, ideal for installations with limited vertical space. The flexible seat ensures a tight seal.

Principle: Disc moves linearly; stem rotates inside the brass nut.

Applications: Water distribution systems requiring reliable shut-off in tight spaces.

2. Type "A" Non-Rising Stem Resilient Seated Gate Valve

This type features reinforced components for improved durability. Smooth operation under medium pressure is guaranteed.

Principle: Non-rising stem with resilient sealing.

Applications: Municipal water, commercial buildings, medium-duty industrial pipelines.

3. Rising Stem Resilient Seated Gate Valve

Rising stem valves visually indicate open/closed status. Resilient seat reduces water hammer.

Principle: Stem rises with valve opening for clear position indication.

Applications: Water networks, industrial pipelines needing position visibility.

4. Resilient Seated Gate Valve Operated With Bevel Gearbox

For large-diameter pipelines, the bevel gearbox reduces manual torque and allows precise control.

Applications: Large water mains, irrigation, high-pressure networks.

5. Resilient Seated Gate Valve Operated With Actuator

Automation-ready valves enable remote operation and SCADA integration.

Applications: Smart water systems, automated industrial processes.

6. Directly Buried Soft Seated Gate Valve

Designed for underground installation, corrosion-resistant, suitable for harsh environments.

Applications: Buried water mains, urban distribution pipelines.

7. Non-Rising Stem Metal Seated Gate Valve

Metal seating provides durability for abrasive or high-temperature systems. Compact design due to non-rising stem.

Applications: Industrial cooling, power plants, chemical processing.

8. Rising Stem Metal Seated Gate Valve

Combines metal seat and rising stem for position visibility and extreme condition performance.

Applications: High-pressure systems, industrial pipelines, municipal water treatment.

Conclusion

Selecting the right gate valve depends on space, pressure, automation needs, and medium. Whether resilient seated or metal seated, rising or non-rising stem, Juhan Valve provides reliable solutions for diverse water system applications.

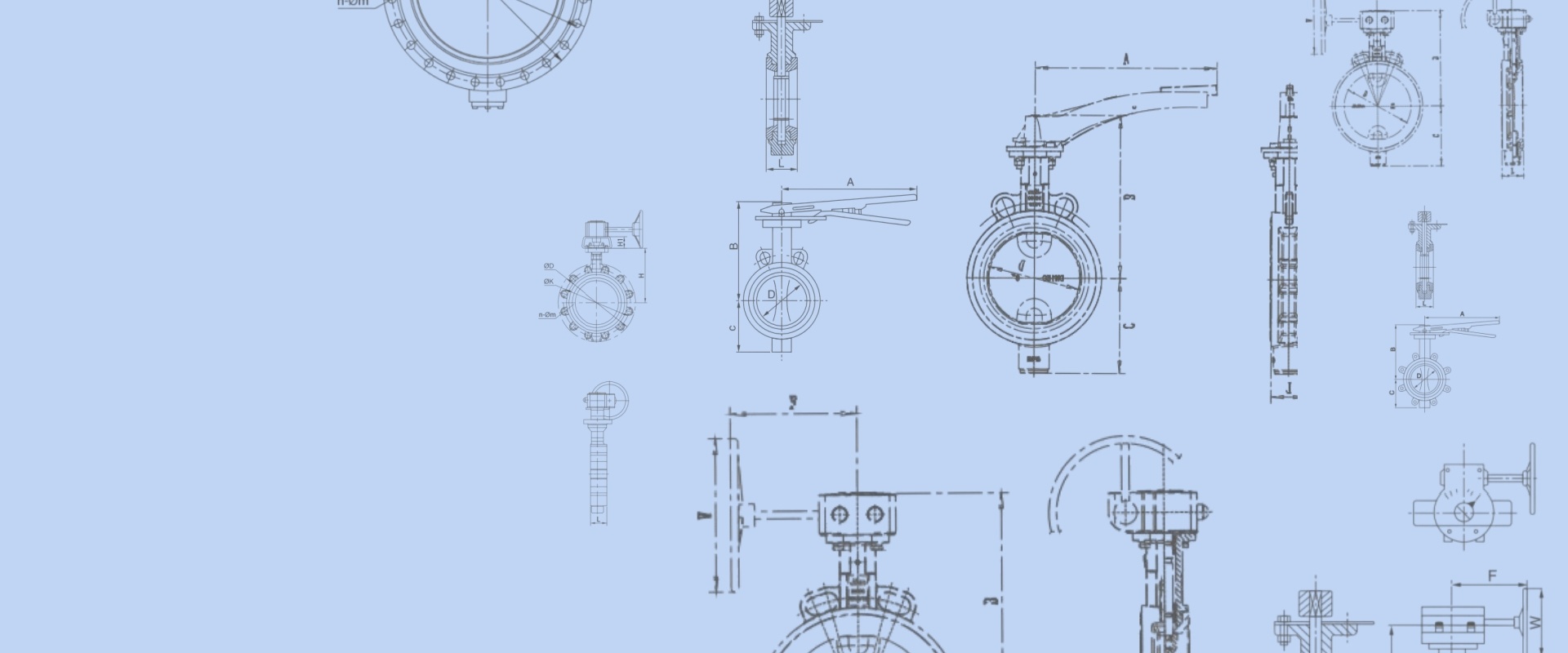

*Images are optional; actual product may vary by specifications.*