Why Pinless Design is the Better Choice - JUHAN valve

Release time:2025.08.28

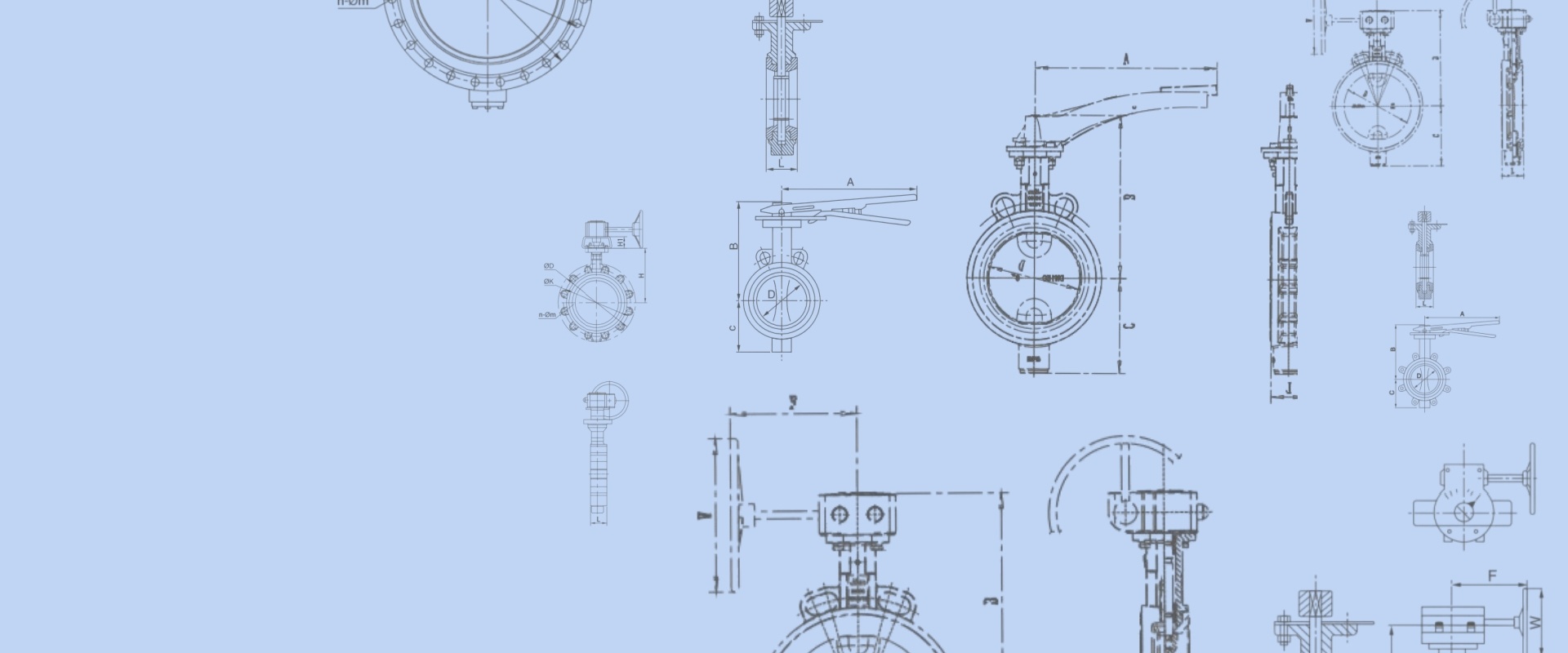

Understanding Butterfly Valve Structures: Why Pinless Design is the Better Choice

When selecting flanged butterfly valves for industrial projects, the design and connection structure between the disc and the stem play a critical role in performance, durability, and leakage prevention. This article explains the differences between traditional pinned connections and modern pinless designs, and why choosing a high-quality, pinless butterfly valve can improve system reliability.

Background of Project Requirements

In a recent project—Beijing BOE Silicon-Based Microdisplay Plant—the specifications for low and medium pressure flanged butterfly valves included:

- The valve body and disc must both be made of stainless steel

- The disc and stem should use a self-tightening pinned structure

However, JUHAN Valve recommends an upgraded pinless connection for superior performance and durability.

Our Manufacturing Process

JUHAN’s 304 stainless steel concentric flanged butterfly valves are designed with:

- Valve body and disc: High-quality stainless steel (SS304)

- Disc and stem connection: Hexagonal pinless design

This modern approach eliminates traditional fixing pins and provides multiple technical benefits.

Pinless vs. Pinned Design: Key Advantages

1. Reduced Leakage Risk

Pinless design eliminates leakage paths, while pinned design may have leakage through drilled pin holes.

2. Avoids Stress Concentration

No pin holes mean no stress concentration caused by machining errors, while pinned design may create early failure points.

3. Enhanced Durability Under Load

Pinless design performs better under alternating loads and is less prone to cracking during long-term operation.

Why Choose JUHAN’s High-End Pinless Valves?

- Superior sealing performance

- Longer service life with minimal maintenance

- Precision-engineered for critical applications

Applications

- Water treatment systems

- HVAC projects

- Industrial pipelines

- Chemical processing plants